Hydrogels are hydrophilic polymeric materials that can absorb water without dissolving. They are polymer matrices that provide structured aqueous environments. Common naturally occurring hydrogels include collagen, gelatine, fibrin, elastin, alginates, chitosan, agarose and hyaluronic acid. There are also a number of synthetic hydrogel materials such as polyethylene glycol (PEG) and polyacrylamide based gels.

These materials can find uses in applications as diverse as three dimensional cell supports, tissue engineering, drug delivery devices, contact lenses or wound dressings.

By using Dolomite microfluidic technologies to form hydrogel beads of specific sizes, users can compartmentalize cell cultures, control drug delivery rates or encapsulate functional materials amongst other applications.

In a single word, yes! Emulsion droplet size can impact how flavors and aromas are released from emulsions such as hot chocolate and mayonnaise. Size also impacts the speed at which drugs or agrochemicals are delivered and released, and the length of time needed between treatments.

Microfluidics provides a tool to manipulate liquids, gases, droplets, cell and particles within micro-channel geometries. The generation of droplets involves controlling the jetting to dripping transition when liquid droplets are pushed into a carrier fluid via a specific chip geometry. The droplets are stabilized using surfactants to avoid coagulation and separation.

Among its various advantages, microfluidic technology has the ability to create three-dimensional flow patterns that achieve precise control over immiscible and miscible fluid mixing.

Droplet-based microfluidic systems have shown unparalleled advantages for the synthesis of monomer- or polymer-containing droplets inside which the hydrogel structures can be formed using various chemical methods. By precisely controlling the formation of the droplets, we can produce hydrogel particles with well-defined sizes, shapes and morphologies.

Production of monodisperse hydrogel beads is achieved using the mechanism of droplet breakup. Two immiscible liquid phases meet at the microfluidic chip junction where the local flow field causes droplets to pinch off in a reproducible way giving droplets of precise and tunable sizes. Subsequent gelation or curing of the droplets results in the formation of hydrogel beads.

Some hydrogel applications, for example agarose, require special temperature control. Dolomite offers a comprehensive microfluidic system whereby temperature control can be set to specific stages of production.

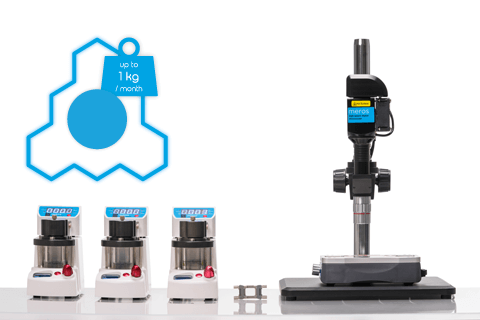

Dolomite’s Single Emulsion Systems are the perfect solution for this application as they utilize microfluidic methods to directly generate monodisperse droplets or emulsions, eliminating the need for further processing. They can be used to generate droplets ranging in size from 2 to 200 µm, resulting in formulations such as water in oil (w/o) or oil in water (o/w) emulsions.

Methodology for monodisperse agarose particle production using microfluidic droplet methods, with particle sizes varied between 20 µm to 130 µm.

Methodology to demonstrate a colorimetric based quantification of protein encapsulation in micrometer sized solid gelatin particles.

Methodology for encapsulation of CHO cells in aqueous droplets using microfluidic droplet methods.