Gas bubbles have a growing number of uses in R&D, engineering, medical diagnostics and as contrast agents for imaging. In the food industry they are used for texture tailoring, or fat reduction. Elsewhere, they’re used in detergents and cleaning products to deliver key active ingredients, in the petroleum industry for natural gas recovery, in material sciences for the synthesis of mesoporous materials, and in clinical applications for targeted drug delivery.

Micron-scale gas bubble generation is an area of growing interest in the microfluidic community. It has opened a new opportunity for compartmentalization of liquids/fluids for highly controlled formulations such as gas-liquid and gas-liquid-liquid emulsions. Closely related to gas bubbles are foams, which are formed by trapping pockets of gas in a liquid or solid. In most foams, the volume of gas is large, with thin films of liquid or solid separating the regions of gas.

In a single word, yes! Emulsion droplet size can impact how flavors and aromas are released from emulsions such as hot chocolate and mayonnaise. Size also impacts the speed at which drugs or agrochemicals are delivered and released, and the length of time needed between treatments.

Microfluidics provides a tool to manipulate liquids, gases, droplets, cell and particles within micro-channel geometries. The generation of droplets involves controlling the jetting to dripping transition when liquid droplets are pushed into a carrier fluid via a specific chip geometry. The droplets are stabilized using surfactants to avoid coagulation and separation.

Among its various advantages, microfluidic technology has the ability to create three-dimensional flow patterns that achieve precise control over immiscible and miscible fluid mixing. Gases can be used to create aerobic or anaerobic conditions within droplets or beads, or to alter the density.

Traditional methods for bubble generation rely on a nozzle emitting gas into static fluid, or agitation to mix a gas and liquid in the presence of a surfactant. These methods of foam production commonly result in polydisperse media, where the gas present is formed into gas bubbles of many different sizes. The reliable production of bubbles with controlled size is recognized to be a challenging process; there remains a need for a widespread, low cost and energy efficient production method.

Microfluidics offer the ability to tune the volume fraction of the gaseous phase from zero to one. The rate of flow of the fluids through the microfluidic chip device determines the mechanism of formation of bubbles. Microfluidic devices are capable of producing uniform bubbles from a few to tens of micrometres in diameter with a narrow size distribution.

Bubble generation using flow focusing methods depends on the pressure balance at the microfluidic chip junction between the gas phase and the liquid (carrier) phase. To make bubbles of tunable sizes the gas pressure is kept constant and the carrier pressure is varied. This changes the carrier to gas pressure ratio at the microfluidic chip junction and the flow of the carrier phase alters accordingly.

Rough estimates of bubble frequencies are between 10 to 1000 bubbles per second. Generally, higher total flows generate higher bubble generation rates. However, increasing the gas pressure (or reducing the liquid pressure) results in larger bubbles. Reducing gas pressure (or increasing water pressure) produces smaller bubbles.

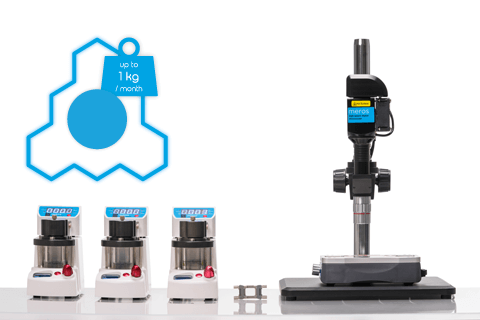

Dolomite’s Single Emulsion Systems are the perfect solution for gas bubble generation, as they utilize microfluidic methods to directly generate monodisperse droplets or emulsions, eliminating the need for further processing. They can be used to generate droplets ranging in size from 2 to 200 µm, with complete control over the amount of gas introduced, allowing the formation of gas bubbles in both hydrophobic and hydrophilic environments.

Methodology for production of micrometer sized gas bubbles and initial operating conditions for research into foam production.

Methodology to demonstrate generation of monodisperse gas bubbles in the 6 µm to 40 µm diameter size range.

This publication highlights the rationale the development of and in-house approach to microbubble generation.